Hardscape and Exterior Details

One of the most distinctive elements of the Coval House is the hand-split cedar siding. A wood so rare in today’s world of construction materials, few people recognize it for what it is, even an internet search reveals virtually no information about this remarkable material and craft. When the home was first constructed in 1948,hand-split cedar siding was likely a premium material even then. Requiring large, clear, old growth cedar logs to even begin the splitting process meant a search in the forest for suitable logs, which were usually already fallen trees hidden on the forest floor. Once acquired, an archaic skill nonexistent today was used to hand-split long lengths, on the average 12’ wide by 1” thick by 12’ long, using a froe. The froe was hammered into a cedar cant then twisted, breaking a tapered section away from the log. The froe was next slipped further down the log repeating the twisting motion until a full length of siding was liberated from the log. The telltale mark of hand-splitting using a froe is a scar across the grain, every six feet or more if luck has it. This marks the twisting of the froe.

When the Covals purchased the house in 1981 it still was sheathed in the original hand-spit siding installed in 1948 by the Starrs. Appreciating the quality and the rarity of the material, and the remarkable skill it took to install it, Myer set out to acquire more of the material to side the extensive additions on the home. His exhaustive search led him to, as fortune would have it, Oliver Purdy, the man who provided the siding to the Starrs in 1948. Bythen Oliver was too advanced in years to split the siding himself, but not too old to teach the craft to a few young men who successfully provided the cedar to the Coval project. Installing the cedar planks is a laborious, exacting process. Since the backs are not sawn flat but are naturally irregular, each piece must be carefully shaped and fitted to the previous board, which also has its own unique irregular shape. Mitered corners demanded the most careful craftsmanship and were painfully uncompromising. Since each plank had its own shape and size, two different boards could not meet at an outside corner. Instead, a single board had to cut, mitered and wrapped continuously around the two walls, not only providing a precise fit but making for a quiet visual continuity as well. On the Pool Room, exterior woodworking is all solid Bubinga hardwood, due to the fact that the roof structure is timber framed. The actual structure of the complete room is fully exposed inside and out, yielding a stunning visual effect.

The Entry Doors were crafted from a Black Walnut tree reclaimed from a home in West Seattle, which after cutting took years to air dry. David Paul Eck did the woodworking, and the stained glass by crafted by Loretta Werner. The doors are constructed with mortise and tenon joints andcross-pinned with Gaboon Ebony, also used in the detail trim.

The roof is the highest quality hand split cedar, split extra thick just for the Coval House. Since the house uses full heated envelope energy efficient construction, the cedar roof requires a one-inch air spacebeneath the shakes to provide proper ventilation. Stainless steel and copper vents assure free airflow under the shakes. On the Pool Room and the Tree Loft a heavy gauge, standing seam copper roof is utilized, assuring generations of service and easy maintenance. All gutters are either solid copper half round systems provided by Alaska Copper and Brass, or custom formed copper and stainless steel gutters and downspouts, depending on specific location. All exterior metal work, including roof valleys, drain covers, downspouts, vents and flashing are again either copper, stainless steel or bronze, proving both longevity and beauty to the structure.

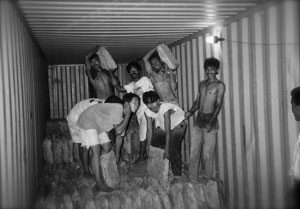

The granite driveway is fashioned from antique handmade pavers reclaimed from old Javanese buildings in Indonesia, built for the Dutch who colonized Jakarta and the surrounding region. The pavers were acquired through David Smith Antiques, who arranged a container load of the stones to be shipped from Jakarta to Seattle for the Coval house. A substantial inventory of stone remains on the estate, ready for expansion of the driveway areas or other uses. Dan Gagnon of All Masonry installed the granite driveway with a Bluestone border, which blends into the entry walkway and stairs, also in Bluestone. Buried next to the driveway is fully engineered, massive storm drain retention system. This system will handle all run-off water from the estate, and then some. To the south of the estate are two more distinct and secluded patio areas. The East Patio is again fashioned in bluestone and granite, and is accessible through the Pool Room doors. The West Patio area is tiled, flowing uninterrupted from the house interior. Both patios are enveloped by a stunning perennial garden, and are connected via granite stairs.

Irrigation and outdoor lighting are managed automatically via Power Line Carrier (PLC) technology, using X10 receivers and transmitters. Lighting utilizes 12-volt underground transformers. Irrigation water is provided by the estate well, delivering 40-50 gallons per minute. Computer scheduling allows manipulation of both lighting and irrigation based on a number of preset parameters.

A Sport Court is located on the north border of the property, secluded from the pond area and accessible via granite stairs. The court can be lit for night use.